| Circuit board corrosion [message #18766] |

Wed, 22 May 2013 11:43  |

toopicky

toopicky

Messages: 50

Registered: September 2011

|

Member |

|

|

This amp still works pretty good but all of the boards have this corrosion on a lot of the resistors where the leads come through the board. My original plan was to re-cap this amp and try to get the effects working, but when I recently pulled it out of the case, I found this. Now I'm wondering if it would still be worth the effort. Is there a way to remove the corrosion?

Any thoughts?

Here is a photo. I hope you can see what I'm talking about.

[Updated on: Wed, 22 May 2013 11:45] Report message to a moderator |

|

|

|

|

|

|

|

|

|

| Re: Circuit board corrosion [message #18772 is a reply to message #18766] |

Thu, 23 May 2013 00:06   |

chicagobill

Messages: 2006

Registered: April 2003

|

Senior Member |

|

|

I keep telling you Pleat, you know more than a lot of techs out there. His other photos show an K200A-4 head in blue.

I don't think that the resistors have been removed, that kind of flux migration is more typical of when the solder joints have been reflowed with too hot an iron. I don't see it all over the board just that row of parts. I use denatured alcohol on a cotton swab to remove that flux residue.

The replaced transistor was done by a lazy tech who didn't want to remove the board to do it right. Sometimes this works, and sometimes it doesn't. If the solder on the underside of the board gets too hot it can cause a cold or loose connection.

And to toopicky, I don't recommend a shotgun recap of the FX boards. I don't see a lot of cap failures in these amps. The only exception to the rule are certain electrolytic caps.

|

|

|

|

| Re: Circuit board corrosion [message #18773 is a reply to message #18766] |

Thu, 23 May 2013 11:52   |

toopicky

toopicky

Messages: 50

Registered: September 2011

|

Member |

|

|

So, it shouldn't be a problem, right? I'll try to clean it just because.

Also, I am aware that the effects require the footswitch and I have tried grounding them to see if they work. Here is what happens:

First, the trem can be heard slightly, but is very noisy. A loud hiss that gets louder as you turn it up and you can hear a slight pulsing sound.

Second, the boost does seem to work sometimes. I'm thinking that the switch may need cleaned since it makes a VERY loud popping and crunching sound when it is switched and the boost will sometimes come on.

Third, the clipper doesn't seem to work at all. At least not that I can tell. I can't hear any change.

Fourth, the reverb is very weak, almost nonexistent, but if I even tap a little on the amp at all I can hear a reverb like sound inside, if you know what I mean. It's also quite noisy.

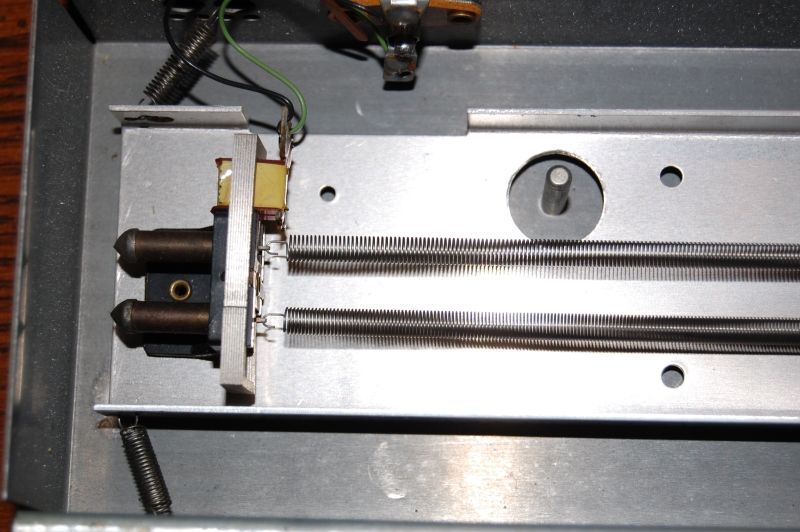

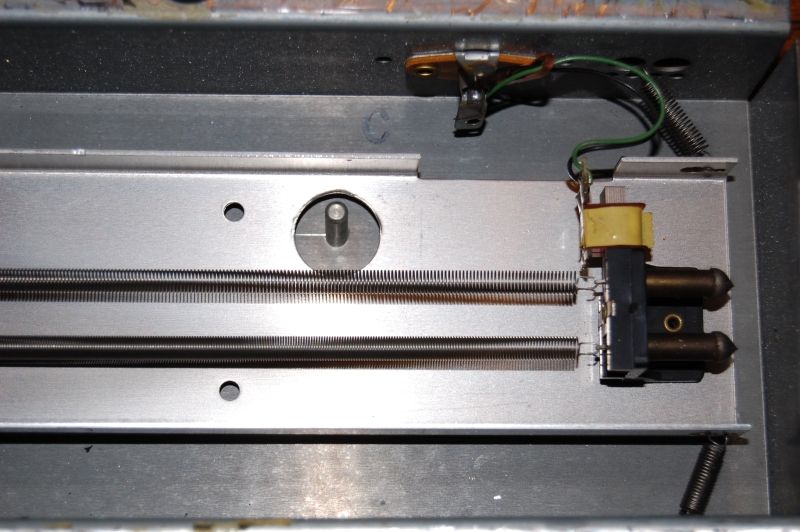

I opened the reverb and didn't find anything broken, however the springs seem like they may be stretched out. You can see in the bottom of the pan where the springs have been rubbing on it (I should get a photo of it so you can see what I mean). Everything that should be plugged in, is and all connections seem to be good, tight and clean.

Any ideas? And thanks for the info. I'm determined to get this thing working.

|

|

|

|

| Re: Circuit board corrosion [message #18774 is a reply to message #18766] |

Thu, 23 May 2013 12:32   |

chicagobill

Messages: 2006

Registered: April 2003

|

Senior Member |

|

|

My first question is do you have a multimeter to check things?, and the second question is do you have the schematics for your amp?

Kustom FX use transistors to switch the circuits in and out and on and off. Because of this, a bad switch transistor can cause an effect to either not work at all or to work weakly or noisily. This might be what is wrong with the trem/vib circuit and the Clipper.

The reverb sounds like the return signal and circuit are working okay, that's why when you shake the tank it rattles through the speaker. So the problem is in the input of the tank or the drive from the amp.

Even though the wires look okay inside the tank, they still may be the problem. Try switching the two tank wires and then shake the tank. Do you hear the springs rattling through the speaker? If you do, then the tank is okay and the problem is in the send wire or the drive circuit. If you don't, then the tank is the problem.

If you have an ohm meter, read the resistance across both of the RCA jacks on the tank. There should be somewhere around 200 ohms on either one. Use the meter to test the cables themselves and also be sure that the RCA jacks and plugs are clean and making good contact.

Let us know what you find out.

|

|

|

|

|

|

| Re: Circuit board corrosion [message #18776 is a reply to message #18766] |

Thu, 23 May 2013 15:16   |

chicagobill

Messages: 2006

Registered: April 2003

|

Senior Member |

|

|

The rubbing on the label is a sign that the amp has been shipped a lot, like in a truck or a car on the road being bounced up and down.

I used to see that all of the time in old Fender amps that lived in the trunk of a players' car. It also shows you how well made those old tanks used to be. Modern tanks will not stand up to that kind of abuse.

Did you try reversing the in and out wires to see if the tank still made noise when rattled?

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Re: Circuit board corrosion [message #18789 is a reply to message #18766] |

Fri, 24 May 2013 18:45   |

chicagobill

Messages: 2006

Registered: April 2003

|

Senior Member |

|

|

The springs may be streched out, as that will happen with age, etc. Originally the springs are of different lengths and are wound in different directions. It's all supposed to made the reverb sound more natural.

If there is no crashing sound when you reversed the wires, then either the input coil is open or one of the two small wires that connect the coil to the RCA jack is open. Now is when you need to have an ohm meter to find out where the problem is.

Accutronics has been sold to a Korean company (Belton), but they make a similar tank as a replacement. They can be purchased from any of the major music electronics companies, like Antique Radio Supply or Mojo, etc. I think that the new tanks sound different from the old ones, thicker, more complex sounding, less clear.

You can also check with the old US factory to see if they can rebuild the old tank, as they were offering this service on eBay. They also make the Morley pedals here in Cary, Illinois.

But you should check the input coil and wires first, as you may be able to fix it.

|

|

|

|

|

|

|

|

| Re: Circuit board corrosion [message #18796 is a reply to message #18766] |

Sun, 26 May 2013 00:40   |

chicagobill

Messages: 2006

Registered: April 2003

|

Senior Member |

|

|

Pleat, the memo is referring to dc resistance values, the tubes and more listing is talking about ac impedances, two different things.

The listed tank should work as a direct replacement, but the input jack may need to be grounded for it to work. Most all K200 amps use a grounded input jack because one of the cables is not grounded on the amp side.

|

|

|

|

|

|

|

|

| Re: Circuit board corrosion [message #18800 is a reply to message #18766] |

Sun, 26 May 2013 13:34   |

chicagobill

Messages: 2006

Registered: April 2003

|

Senior Member |

|

|

Looking at the photos of your tank, both input and output jacks are grounded. If the jack is insulated, there will be a brown phenolic wafer that keeps the shell connection of the RCA jack from touching the metal chassis of the tank.

In order to ground the insulated jack, a small jumper wire needs to be soldered from the shell connector to the mounting bolt. Just a basic soldering job. Do you have a soldering iron and basic soldering skills?

Pleat, as far as I know, all T&R Kustom amps used tanks that were grounded at both input and output. I would have to look up all of the schematics to prove this one way or another.

Personally, I'm more into the wide panel heads, and these came with tanks with grounded jacks. They also would run a separate ground wire from the chassis to the tank shell. This creates a ground loop that causes hum in the amp.

In the K200A and later heads, they disconnected the ground from one of the two cables at the pc board to eliminate the ground loop.

|

|

|

|

|

|

VintageKustom.com

VintageKustom.com

]

]